[BACKGROUND]

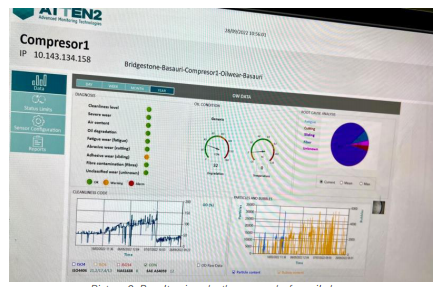

The plant is equipped with 6 screw compressors that supply plant air to the entire complex. Given their high criticality, this equipment’s condition and maintenance are vital. The working cycle of these compressors is defined by the hours of use, 24/7; having one of in continued while another one is set as “back up” in automatic mode (without load), with oil circulating at a controlled temperature.

Before installing the sensors, the compressors were checked every 6 months and the oil was changed at regular intervals without knowing if the oil had reached its maximum lifespan.

[CHALLENGES]

HSSE (Health, Safety, Security & Environment) savings due to reduced oil consumption

[SOLUTION]

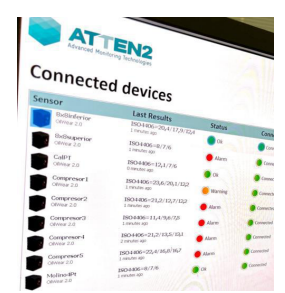

After seeing the benefits of our technology, they installed the OilWear sensors. These sensors not only ensure the optimal lifespan of the oil by providing detailed information about its degradation level, but they also monitor the compressor’s condition through the fluid. Our particle counter with shape analysis enables root cause identification and bubble counting, offering higher accuracy and enhanced performance.

[CUSTOMER BENEFITS]

Extended the life of the oil x 4.

Extended oil change interval from 6 months to 2 years.