Enhancing detection and monitoring of oil degradation and water contamination in oil

[INTRODUCTION]

In the dynamic realm of industrial operations, the optimal performance of hydraulic systems is crucial for sustained productivity and equipment longevity. Hydraulic systems serve as the backbone of various industries, powering machinery and facilitating essential processes. However, ensuring the seamless operation of these systems requires advanced monitoring and maintenance practices.

Traditional approaches to monitoring hydraulic systems often lack the precision needed to detect subtle issues, leading to unforeseen challenges and reactive maintenance. Recognizing the critical importance of a proactive and technologically advanced approach, the integration of online sensors tailored to monitor water presence and degradation in hydraulic systems emerges as a transformative solution. Particularly significant is the focus on the prevalent failure mode associated with degradation by-products and varnish, where particles are notably smaller than conventional contamination monitors can detect.

These systems are equipped with super-efficient filtration systems where most particle presence is effectively eliminated. However, the primary concern lies in the degradation by-products and varnish, especially given the susceptibility of MOOG valves tvalve sticking, a failure mode directly linked to oil degradation. This failure scenario is enhanced in systems that do not operate continuously due to temperature changes and varnish solubility.

It's imperative to highlight that hydraulics don't fail primarily due to particle presence; the critical factor is oil oxidation. The OilHealth Probe Max (OHPM) proves invaluable in this context, as, in addition to degradation measurement, it detects water parts per million (ppm), acting as a crucial precursor to potential oil degradation. Water in oil accelerates oil degradation up to 10 times.

[CASE]

An automotive plant managing multiple hydraulic systems grappled with failures stemming from the presence of oil degradation by-products and varnish, with particles too small for conventional technologies to detect. To address this critical challenge, the plant adopted an advanced approach by deploying an online sensor suite.

The OilHealth Probe Max (OHPM) was installed in the auxiliary circuit, which encompasses integral cooling and filtration systems susceptible to water contamination. The OHPM not only focuses on detecting water parts per million (ppm) but also plays a pivotal role in anticipating potential oil degradation. This integration emphasizes a proactive and technologically advanced solution to combat hydraulic system failures associated with degradation processes.

A system outage carries significant implications, encompassing the potential disruption of an entire work shift, necessitating the replacement of the

MOOG valve and lubricant, and addressing additional process issues like scrap residues in the production line. These events incur an average cost

of €1,500 per hour, excluding materials.

[SOLUTION]

It was recommended that OilHealth Probe MAX sensor should

be installed to obtain the following information:

Oil degradation

Fluid temperature

Water presence

Water PPM & %

[RESULTS]

Following months of continuous monitoring, valuable insights were gleaned from the online sensor suite, notably the OilHealth Probe MAX.

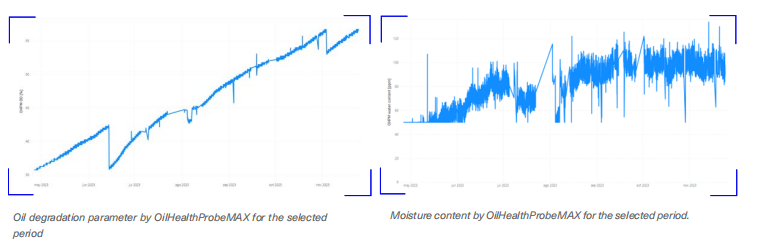

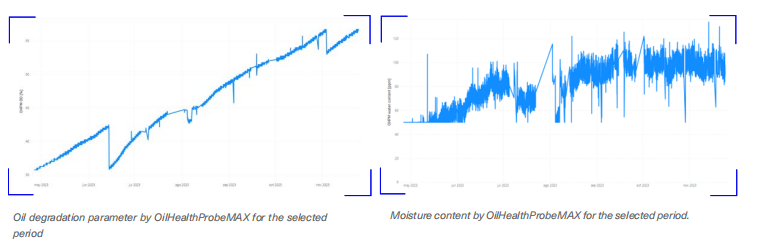

Two key parameters, oil degradation and moisture content, were meticulously tracked and correlated with laboratory measurement during the selected period, as illustrated in the previous figures.

[Water presence (PPM) against RH% online sensor]

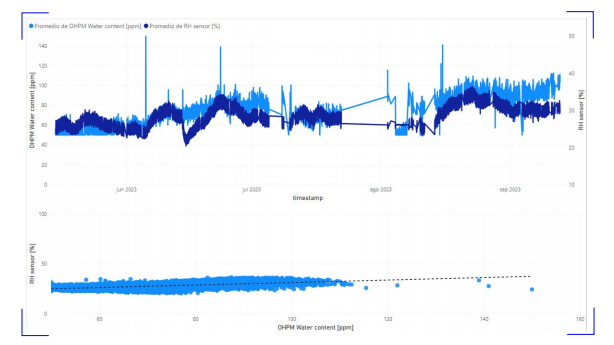

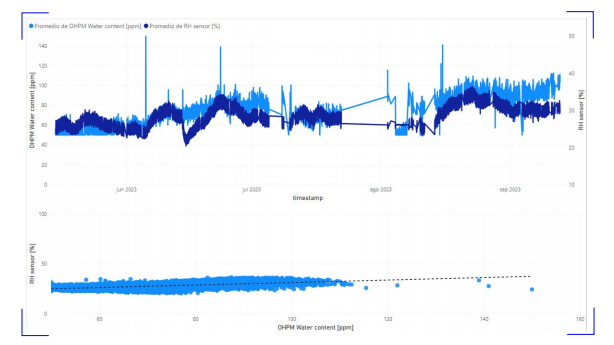

In this specific setup, a Relative Humidity (RH%) online sensor was strategically installed in tandem with the OilHealth Probe MAX along the same hydraulic line. This configuration facilitated a direct comparison between the water detection capabilities of the OilHealth Probe MAX and the RH% online sensor. Remarkably, over the measurement period, both sensors demonstrated a significant correlation between their measurements, as depicted in the following figure.

Additionally, OHPM results exhibit a robust correlation with Karl Fischer titration (KF) results from internal lab testing, showcasing the effectiveness of this comprehensive and technologically advanced approach to mitigate hydraulic system failures.

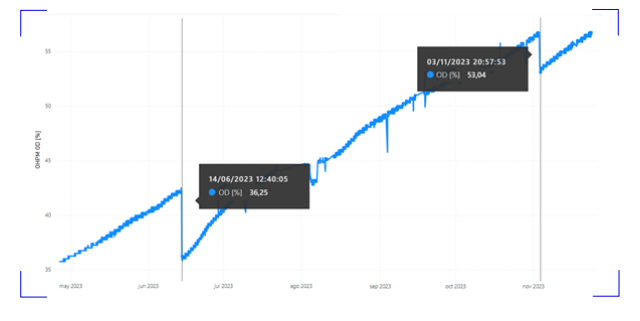

[OD oil top-up detection]

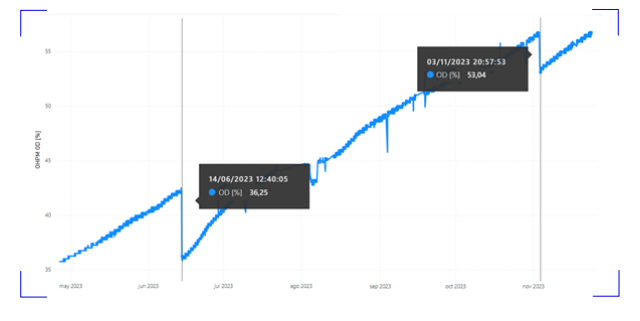

One of the distinctive advantages of Atten[2]'s online technology is the ability to provide a direct visualization of maintenance actions' effectiveness. In this specific case, the system detected two instances of oil top-ups, represented as sudden improvements in oil condition. This capability, referred to as OD (Oil Degradation) oil top-up detection, showcases the system's ability to not only identify issues but also to directly correlate them with maintenance interventions, offering a tangible measure of operational efficiency

[Summary]

In response to hydraulic system monitoring requirements in an automotive plant, an innovative solution was implemented. The introduction of an online sensor suite, featuring the advanced OilHealth Probe MAX (OHPM), focused on the auxiliary circuit with integrated cooling and filtration systems. After months of monitoring, two critical parameters, oil degradation and moisture content, were tracked using the OHPM, yielding valuable insights.

Furthermore, the system's ability to detect and visualize maintenance actions showcased the practical impact of the Atten[2] online technology. [ This comprehensive approach not only identified issues but also provided a

tangible measure of operational efficiency, emphasizing the transformative potential of advanced sensor technologies in hydraulic system management. ]