[BACKGROUND]

Maintenance costs in the mining industry are usually between 30-50% of total operating costs. - Topal and Ramazan, 2010

This is why the best maintenance professionals in the sector are committed to advanced maintenance solutions, such as Atten[2] sensors.

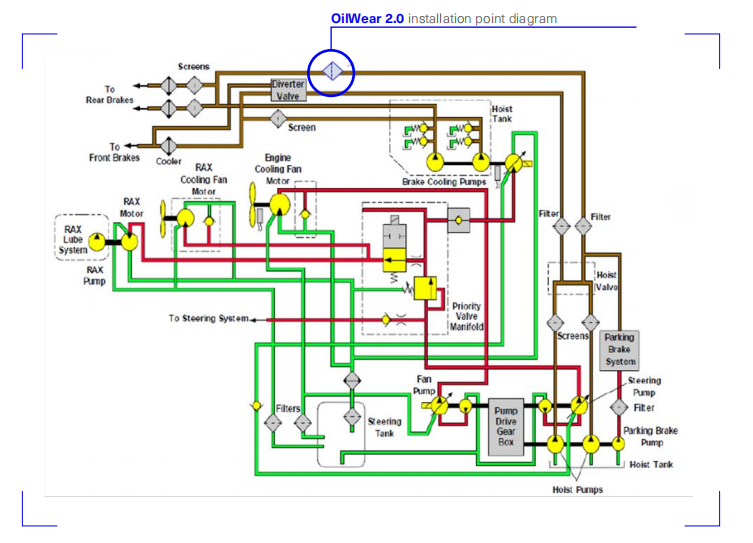

At a coal mine in Colombia*, an advanced microfiltration monitoring solution was implemented for truck hydraulic system contamination control optimization.

[CHALLENGES]

Avoid unscheduled downtime

Optimize scheduled shutdowns, acting effectively upon failure

[SOLUTION]

Wear mode shape analysis

Image storage

[RESULTS]

STATUS

ISO4406

Before filtration

22/17/14

After filtration

20/16/13