BACKGROUND

In the past, existing predictive maintenance equipment could not identify damage to a bushing, leading to a catastrophic failure of a primary crusher costing $1,000,000. To enhance lubrication management and machine maintenance, the customer

conducted a comprehensive assessment of predictive maintenance technologies for their primary crusher. They then integrated Atten[2]’s OilWear S sensors into their operations.

Before this implementation, their lubrication management cycles typically took at least a week, involving sampling, laboratory analysis, and decision-making.

CHALLENGES

SOLUTION

Given this customer’s needs, Atten[2] recommended the installation of OilWear S sensors. The ISO code display and real-time particle shape classification enabled quick decision-making:

The lubrication management cycle went from one week to one or two days, reducing risks in sampling, reducing lab and labor costs, and thus increasing machine lifetime.

Atten[2] sensor offers a unique combination of:

Image storage

SEQUENCE OF FAULT DETECTION

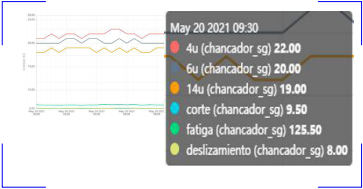

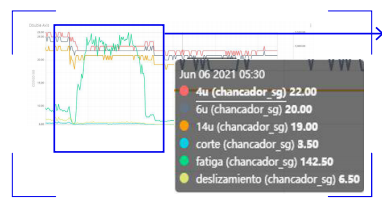

“Normality line” of primary crusher operation was set to an ISO code 22/20/19, as seen in the box, the average data before the failure began.

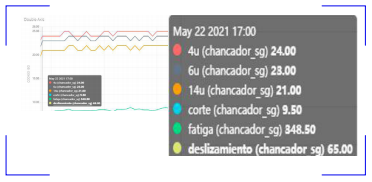

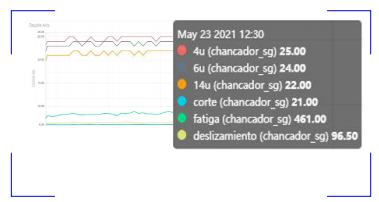

May 23th, 2021

The graph shows a sustained upward trend in the ISO code (25/24/22). Similarly, the classification of particulate matter indicates a continuous increase in cutting and sliding particles.

June 06th, 2021

Thanks to continuous monitoring, an issue with a bushing was detected, associated with the presence of cutting and sliding particles deviating from normal operating parameters. Without Atten[2]’ simaging technology and shape analysis, detecting this damage in time would have been impossible or very difficult. The ability to provide reliable measurement results even with high oil viscosity and strong bubble formation in lower ISO classes, compared to conventional particle counters, is another key advantage that enables early damage detection under harsh conditions as given here with this particular crusher.

CUSTOMER´S BENEFITS

|

Production hours

|

40.000$

|

12 hours

|

480.000$

|

|

Oil change

|

16$

|

8.000 liters

|

128.000$

|

|

Handling, removal, disposal of

used oil

|

8$

|

8.000 liters

|

64.000$

|

|

Labor, structures, spare parts, logistics and commissioning

|

|

|

300.000$

|