Category: Viscosity Measurement

Method Standard: ASTM D1243, ASTM D1795, ASTM D2857, ASTM D3591, ASTM D4243, ISO 1628-1, ISO 5351

Application: Others

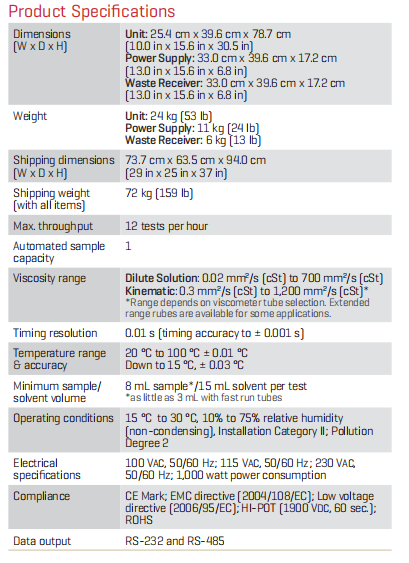

Brand: CANNON

miniPV® is a fully-automated, single sample, benchtop viscometer for testing dilute solution viscosity of polymers in organic solvents and aqueous solutions. The Ubbelohde-style tube covers a dilute solution polymer viscosity range between 0.02 mm2/s (cSt) and 700 mm2/s (cSt) from 15°C to 100°C. Available tubes cover a kinematic viscosity range of 0.3 mm2/s (cSt) to 1,200 mm2/s (cSt) with extended KV range tubes available on request.

Designed to meet specific polymer industry needs

Compatible with organic solvents and aqueous solutions

On-board software with specialized polymer calculations determines relative, inherent, reduced, specific and intrinsic viscosity as well as molecular weight

Integrated TE cooling provides superb temperature control from 15 °C to 100 °C

Dilute solution polymer viscosity range: 0.02 mm2/s (cSt) to 700 mm2/s (cSt). Both single range and special dual range viscometer tubes are available

Available kinematic viscosity tubes cover a range of 0.3 mm2/s (cSt) to 1,200 mm2/s (cSt) with extended range tubes available on request*

Compact, robust design

Fits in roughly the same bench-top area as an analytical balance to conserve valuable lab space

Proven CANNON®viscometer platform offers reliability and outstanding support

Peltier cooling is environmentally friendly and requires no external refrigeration

Fully automated bench-top testing

Software controls the instrument and facilitates tasks such as calibration, data entry, method specification, calculation selection, report formatting, and data exporting

Single PC manages up to 4 instruments using VISCPRO®software

Reduces operator to operator variability

Automated vial washing & drying reduces vial consumption and replaces manual washing

Simplified maintenance & test versatility

Modular bath for easy maintenance access

Operators physically replace tubes in minutes, eliminating the need to schedule related service calls

Single-point temperature calibration avoids need for tube recalibration and maximizes test flexibility

Standard dual solvent input