Wettability:

Pro-Pak is formed from metal through which more than 1,000 tiny holes per square inch have been protruded. Pro-Pak’s unique wetting properties derive from a rectangular network of capillaries on the surface of the metal, produced by the combined effect of the holes and the roughness of the burrs.

This self-wetting property ensures that Pro-Pak stays wet in service in the distillation column and retains its high efficiency. Because the surface area of the packing remains effective under low liquid loadings, high column efficiency is maintained at vapor velocities very much lower than the flooding velocity.

Surface Area:

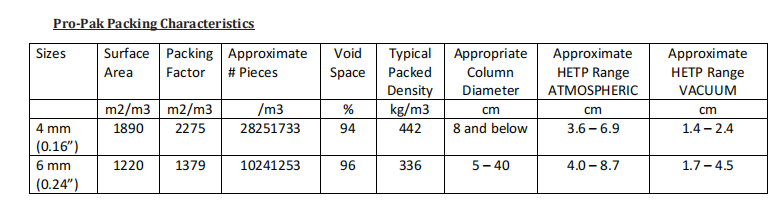

The large surface area made effective by the wettability of Pro-Pak allows for efficient mass transfer between the liquid and vapor phases. The surface area is approximately 576 square feet per cubic foot for the 0.16-inch size and 372 square feet per cubic foot for the 0.24-inch size. The packing

factor is 693 for the 0.16-inch size and 420 for the 0.24-inch size.

Free Space:

High free space is especially important in vacuum distillation (for reduction of pressure drop) and in extractive distillation and absorption (where high liquid or vapor loading is common).

Pro-Pak has high free space (94% for the 0.16-inch size and 96% for the 24-inch size)

Vacuum Efficiency:

As operating pressure is reduced, the efficiency of Pro-Pak increases. For example, when a 2-inch diameter column filled with 0.16-inch Pro-Pak is operated at its maximum rate, the number of theoretical plates more than doubles after the pressure is reduced from 735 to 10 mm Hg.

Holdup:

Holdup depends not only on the packing, but also on the vapor velocity, vapor density, liquid density, etc. Note that the holdup at flooding velocity for n-heptane is considerably more than for the heavier ethylene dichloride. Note also that the flooding velocity for ethylene dichloride is about 45% greater than n-heptane.

0.24" Protruded Packing

Recommended for 2" diameter columns or larger.

Material: Fabricated from metal ribbon of various alloys

Shape: Saddle

Size: 0.24" (6mm) Diameter x 0.24" (6mm) Wide

Pieces per cu. ft.: 290,000

Packed density (for type 316 stainless steel): 21 lb per cu. ft.

Surface area: 372 sq. ft. per cu. ft.

Percent free space: 96%

Packing Factor: 420

0.16" Protruded Packing

Recommended for 2" diameter columns or smaller.

Material: Fabricated from metal of various alloys

Shape: Saddle

Size: 0.16" (4mm) Diameter x 0.16" (4mm) Wide

Pieces per cu. ft.: 800,000

Packed density (for type 316 stainless steel): 27.6 lb per cu. ft.

Surface area: 576 sq. ft. per cu. ft.

Percent free space: 94%

Packing Factor: 693