In the industrial and mining industry, water immersion is unavoidable in engines, gearboxes, hydraulic systems and other machine component during operation. In order to prevent the surface of mechanical parts and components in contact with water and rust, the corresponding engine oil, gear oil, hydraulic oil, etc. are required to have better rust resistance. The rust resistance of lubricating oils is an important indicator of the acceptance of quality of the new machine fluids. The Liquid-phase corrosion test methods commonly used are GB/T11143, ASTM D665 Standard Test Method (Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water). This method is applicable to mineral oils with additives, such as those used to characterize turbine oil, hydraulic oil, and circulating oil, for their ability to prevent rust on iron components when mixed with water.

GB/T 11143 and ASTM D665 primarily involve mixing 30ml of water or synthetic seawater with the oil, simulating operating conditions. A standard steel rod is then immersed in the mixture for a certain period of time, removed, cleaned with solvent, and immediately visually assessed for the degree of rusting. The degree of rusting is categorized into 4 levels:

(1) Rust-free: The test rods are rust-free at the end of the test period.

(2) Light Rusting: Rusting confined to not more than six spots, each of which is 1 mm or less in diameter.

(3) Moderate Rusting: Rusting in excess of the above, but confined to less than 5 % of the surface of the test rod.

(4) Severe Rusting: Rusting covering more than 5 % of the surface of the test rod.

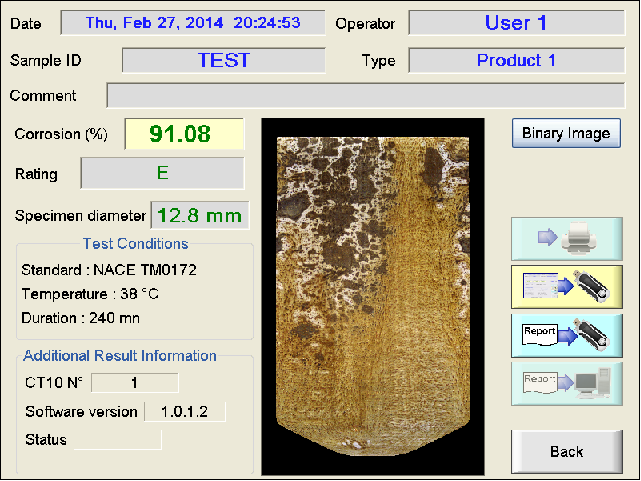

In the rating criteria, phrases like "rust spot diameter not exceeding 1mm" and "rust spot area less than 5% of the surface area of the test steel rod" increase the difficulty of visual assessment by the human eye. The CT10 automatic rust performance grading tester developed by France's AD Systems provides visualized rusting results, enabling precise calculation of the percentage of corroded area and reducing the subjectivity of manual judgment. Test results are documented comprehensively and can be stored in LIMS or USB drives for traceability. The use of uniform and consistent light sources reduces environmental interference, thereby enhancing the repeatability and reproducibility of the results.

The visual algorithm of the French AD Systems CT10 automatic rust performance grading tester eliminates the subjectivity of manual testing, significantly improving repeatability and reproducibility through advanced technological algorithms. It serves as an impartial third eye, resolving disputes over rating. results.