Moisture has a vital impact on the performance of lithium batteries. This includes battery capacity, service life, and safety performance. This is due to moisture further encouraging the formation of hydrofluoric acid (HF) and lithium hexafluorophosphate (LiPF6) in the electrolyte, which will affect the film quality, therefore effecting the entire cycle and safety performance of the battery. Secondly, the water will react with the lithium battery on the surface of the negative electrode to form lithium oxide (Li2O) and release Gas, which consumes lithium ions, increases the internal pressure of the battery, reduces the battery capacity, and affects the safety performance of the battery. For most battery manufacturers, it is important to consider how to control the water content in the lithium battery production process.

Electrolyte moisture is usually measured using the Karl Fischer direct injection test method. When sampling the electrolyte, because the electrolyte is very hygroscopic and requires a very low moisture content, it is recommended to operate in a vacuum glove box and rinse the syringe with electrolyte before injection.

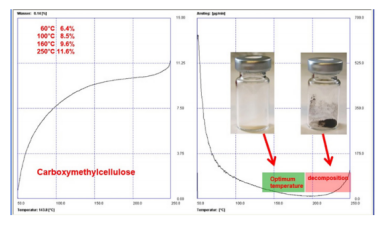

For materials such as positive electrodes, negative electrodes and diaphragms, which are often present in solid or semi-solid form, moisture measurement is generally performed using the Karl Fischer oven unit. Sample moisture measurement using the cassette oven method usually requires heating the sample to a certain temperature and then bringing the evaporated moisture to the coulometric titration cell by means of an external dry carrier gas. Such a measurement method can introduce bias to the moisture results at low levels.

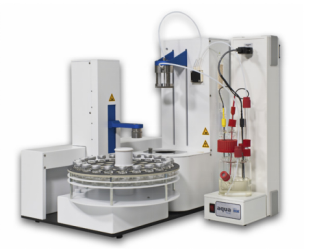

ECH automatic Karl Fischer moisture meter without external carrier gas does not need external carrier gas. It pumps the moisture of the sample into the coulometric titration cell through the internal gas circulation, removing the time needed for gas drying and producing more accurate measurement results. At the same time, it also prevents the volatilization of methanol from the Karl Fischer reagent and pollutes the laboratory air.

ECH automatic Karl Fischer moisture meter without external carrier gas is suitable for testing a variety of battery materials. It has higher test accuracy and a programmable heating program to help product development. ECH automatic Karl Fischer moisture meter without external carrier gas is a better choice for lithium battery moisture detection.